Traditional home use air-conditioning is designed to make people feel comfortable, and it does not provide high refrigeration capacity and cope with high or low humidity function. It cannot adapt to the environment that the electronic equipment is highly centralized. Common constant temperature and humidity is designed for matching the production technology, and both the accuracy and reliability control cannot reach the environmental requirements of precision electronic equipment.

The latest integrated machine developed by our company is designed for the communication room in cold area. Outdoor cold air goes through the filter directly into the computer room for refrigeration, and at the same time the compressor is not running in order to save the energy. It is an integrated design for the unit, so there is no need for outdoor machine. It can provide high precision, high reliability, high performance, and reliable operation.

传统的家用空调的目的是使人感到舒适,它不提供高制冷量和应付高或低湿度的功能。它不能适应电子设备高度集中的环境下。常见恒温恒湿的设计是为了相匹配的生产技术,其准确性和可靠性的控制不能达到精密电子设备环境的要求。

公司开发研制的最新型的一体机可适用于寒冷地区的通信机房。室外的冷空气通过过滤器直接进入通信机房来达到制冷效果,同时间压缩机不运行达到节省能源的目的。它是整体的机组设计,因此不需要室外机。它能提供高精度,高可靠性,高性能,及可靠地运行。

Fields:(应用领域)

Environmental control: communication room, communication base, microwave room, communication station, base station, radio station, transmitting station, relay station, remote sensing receiving station, cold area and etc.

环境控制领域:通信机房、通信基站、电波机房、通信站、基地台、无线电台、发报局、中继站、遥感接收站、寒冷地区等。

Features(产品特性):

- Floor-mount, rack-mount and ceiling-mount modules, plus a choice of cooling capacities, cover any application requirements.

地板、机架和天花板安装模块,再加上选择的冷却能力,适用于任何应用要求。

- Pumped refrigerant solutions are ideal for use around electronic equipment. No water into the room.

理想的泵制冷剂的解决方案适用于周围皆电子设备的场所,没有水进入房间的疑虑。

- Scalable – add or move fan coils as needed.

可扩展的–添加或移动的风机盘管当需要时。

- Energy efficient. Total energy savings potential up to 30% can be achieved with the HIROSS integrated machine solution.

能源效率。总合的节能潜力可达30%透过HIROSS一体机的解决方案。

- Minimal floor space requirements allow more room for IT equipment.

最小占地空间的要求,允许额外的空间放置更多的设备。

- In installation process, the duct uses fast connecting kits, making the installation, upgrading and equipment transfer more convenient and faster.

在安装过程中,管道用快速连接套件,使得安装、升级和设备转移更加便捷。

- Standard RS485 interface is available, realizing remote monitoring system unit and relevant renovation are also available.

标准的RS485接口,可实现系统远程监控,和也提供有关的装修服务。

- High reliability, flexibility, low cost in whole life cycles.

高可靠性,灵活性,整个生命周期成本低。

- When the outdoor temperature reaches a certain range, the compressor can be closed automatically.

室外温度达到一定范围时可自动关闭压缩机。

- Outdoor cold air goes through the filter directly into the computer room for refrigeration, and it is an integrated design for the unit, therefore, there is no need for outdoor machine.

室外的冷空气通过过滤器直接进入制冷机房,一体化的设计,因此,没有室外机的需要。

Energy-saving data & performance of unit (节能数据和机组性能):

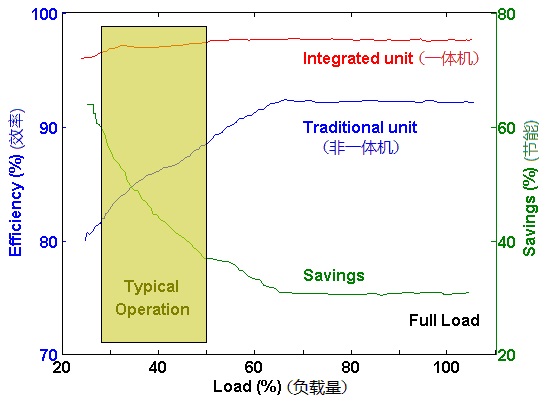

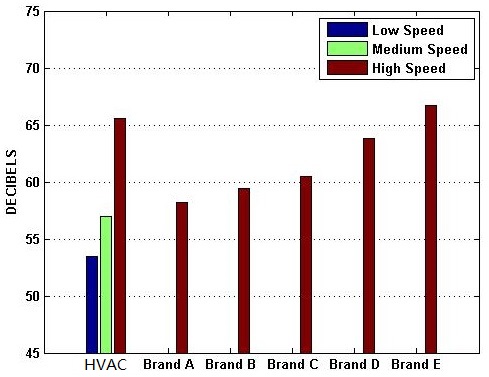

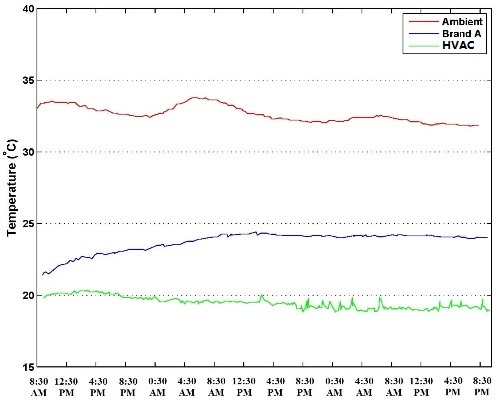

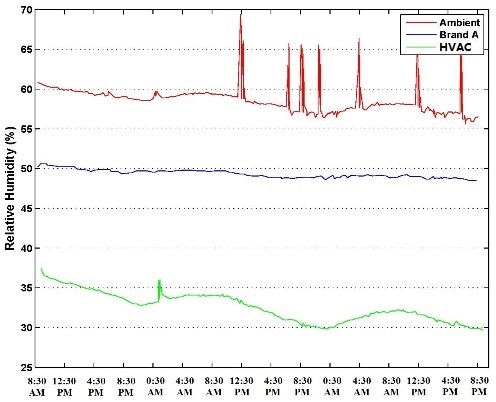

The Engineering Department has created extensive performance and test data, summarized in the charts above and below, across the following categories: energy saving (figure 1), sound performance (figure 2), cooling performance (figure 3), and humidity performance (figure 4). Total energy savings potential up to 30% can be achieved (see figure1).

工程部门已经建立了广泛的性能和测试数据,总结了在下面的图表中,类别分别为:节能(图表1)、声音(图表2)、冷却(图表3)和相对湿度(图表4)等性能。节能潜力可达30%(参考图表1)。

Fig.1

Fig.1

Fig.2

Fig.2

Fig.3

Fig.3

Fig.4

Fig.4

Summary (总结):

As illustrated in the charts above, units with variable-speed fans are significantly quieter than other cooling units. The cooling unit consistently maintained cooler temperatures inside the test room and was able to cycle on and off with ambient temperatures ranging from 33.5°C to 34.5°C (±0.5°C). The cooling unit consistently maintained higher humidity inside the test room with ambient humidity ranging from 30% to 36% (±3%). (See figure 3 and 4)

上面的图表所示,变速风扇的冷却机组比其它品牌冷却机组更安静。冷却机组始终保持凉爽的温度和循环式的开启和关闭,试验室环境温度范围从摄氏33.5度到摄氏34.5度之间(摄氏±0.5度)。冷却机组保持较高的湿度范围,试验室环境湿度范围从30%到36%之间(±3%)。(图表3和4)

Test Conditions (测试条件):

1. The cooling units were tested simultaneously in side-by-side cabinets.

2. The cabinets were located in an enclosed, climate-controlled test room.

3. Each cabinet was filled with 208 bottles (73% capacities).

4. The cooling unit was set to maintain 20°C (19.5°C "off" / +1°C (20.5°C) "on"), and the Brand A was set at 20°C).

1. 测试冷却机组在环境中同时并排测试。

2. 所有测试机组位于封闭气候控制的试验室。

3. 每个冷却机组装满208瓶水(73%容量)。

4. 冷却机组被设置保持摄氏20度(摄氏19.5度“关闭”/ +摄氏1度(摄氏20.5度)“开启”),和品牌A被设置在摄氏20度)。